Custom Plastic Fabrications Follows UPF's Proven Track Record

The decades of successful experience and continual refinements of our polypropylene tanks allowed United Plastic Fabricating, Inc. to open up its new industrial division, Custom Plastic Fabrications, LLC.

It all started in 1986 when United Plastic Fabricating, Inc. was founded in Massachusetts by Joe Lingel and Al Burnham, two successful firefighters who evaluated why fire truck water tanks made of galvanized steel corroded over the years. The corrosion was causing the tanks to leak. For this reason, they wanted to find a solution that would stop these tanks from corroding and thus, leaking. After analyzing different alternatives, they determined that they could use high-impact polypropylene to make the water tanks.

Polypropylene tanks offered weight savings and eliminated the corrosion issue that was prevalent on galvanized steel. As a result, custom plastic fabrication was the solution that stopped the leaking issue. Not to mention that these lightweight polypropylene tanks offered a lifetime warranty. Because of this, they introduced the POLY-TANK®.

Seamlessly, the UPF POLY-TANK® water tank for fire apparatus became the industry standard. The obvious advantages and benefits of polypropylene tanks discontinued most of the steel water tanks in this industry.

UPF also developed other fire services products after the great success of the POLY-TANK®. Those products include slip-on units, large wetside tanks, foam trailers, and elliptical tanks.

Bringing Solutions to Industrial Customers

After the continuous success and the obvious advantages that polypropylene tanks have, UPF decided to bring this solution to different industries other than the fire industry. To accomplish the manufacturing production capacity, UPF opened the Florida and Wisconsin manufacturing facilities. Additionally, UPF moved the Corporate Headquarters in Massachusetts from a 6,400-SF to a 39,000-SF facility in 1992. That is when UPF started the custom plastic fabrication for the trucking industry. As a result, UPF developed the world’s first polypropylene service body in 1994, the PolyBody®.

Since innovation has been our motivation for over 30 years, we knew that our custom plastic fabrication capabilities would succeed in the industrial markets. We started to analyze different tank markets that were being affected by corrosion issues. We found that this is an issue that many different industries face, so we wanted to provide a solution. Our polypropylene tanks for many industries have proven to be superior replacements for fiberglass, concrete, and/or stainless steel.

Additionally, our tanks are 100% rust-proof, extremely durable, lightweight, and are easy to clean. The customers who have benefited the most from our solutions include engineering firms and industrial clients. Therefore, UPF started producing plastic fabricated products for marine & aquaculture, chemical processing, agriculture, food processing, medical industries, etc.

In 2007, Andrew Lingel, Son of Joe Lingel, came to work at UPF, and after continuous improvements, he brought to the company he became the president in 2016. “Andrew has gained valuable experience over the past 10 years working in and with various departments,” said Joe Lingel. “He has proven to be an asset within the organization, and his passion for enhancing processes and efficiency within the departments using lean initiatives has resulted in noticeable improvements.”

My father's success with United Plastic Fabricating, Inc. (UPF) is indeed the American Dream. As a kid, I witnessed his hard work and long hours become a reality. UPF became, and still is, the number one fire truck tank manufacturer in the country. He solved the problem Fire Departments had with the corroded steel tanks by innovating the POLY-TANK®. My dream is to bring custom plastic fabrication solutions to other industries. Whether they have issues with rust and corrosion, weight, or even price, our new division Custom Plastic Fabrications, LLC. (CPF) could be their answer.

Andrew Lingel

Our New Home to Serve Industrial Customers

Based on the successful outcomes that we had and the increased demand for non-fire products, Andrew Lingel decided to open up our industrial division separated from the fire vertical. That’s how ultimately Custom Plastic Fabrications, LLC was born in 2020. Subsequently, we started serving our industrial customers under Custom Plastic Fabrications, LLC.

The custom plastic fabrication products that we have been producing for our industrial customers include high-quality polypropylene tanks for stormwater, pesticide/insecticide, diesel generator manufacturers (DEF tanks), houseboat hulls, custom pontoons, and sewer jetter (hydroblasting) trucks. We have also been manufacturing components for wastewater treatment in the pulp and paper industry, such as anaerobic digesters.

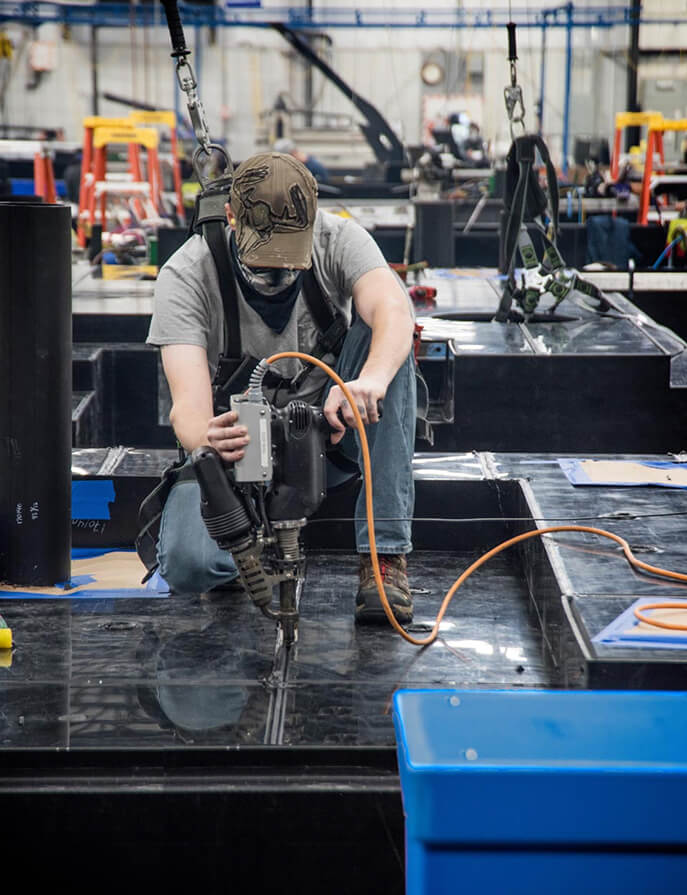

With Custom Plastic Fabrications, LLC, we are staying up to date to use the latest equipment and technologies. We also guarantee superior materials, state-of-the-art manufacturing, and innovative technologies to deliver the best plastic fabrication solutions in the market.

Our goal is to ensure all our products are designed and fabricated to your specific needs. We aim to provide our customers with the best plastic fabricated solutions. On top of having the highest quality product in the market, we also pride ourselves on our product support team for on-site repairs.

As a result of our efforts, we are happy to announce that we intend to become the industry standard for the industrial markets.